Flexible hoses In stainless steel

High performance flexible hoses in stainless steel.

Flexible stainless steel pipes Suitable for the transport of dangerous fluids.

Great availability in stock or with extremely short supply times of metal flexible hoses and quick couplings for chemical, petrochemical, cryogenic, pharmaceutical, explosion-proof, natural gas, power plants, iron and steel, mechanical plants etc. Parallel coiled metal hoses have a perfect seal and excellent temperature resistance. These characteristics, in addition to other peculiarities and specifications, make them particularly suitable for the transport of dangerous or delicate fluids. Parallel coiled metal hoses have a perfect seal and strong heat resistance, therefore they are used to convey a wide range of fluids within wide temperature limits. Being perfectly sealed, they are used in the chemical, petrochemical, cryogenic, nuclear, thermal, natural gas and various other sectors. They allow applications with static assembly or with cyclic movements

FLEXIBLE HOSES OF THE BEST BRANDS

Posa Tubi offers its customers a vast assortment of rubber hoses for high and very high pressures, with great availability ready for immediate delivery from the best brands such as Interpump, Manuli, IVG Colbacchini spa, Hoses Technology.

INTERPUMP RANGE

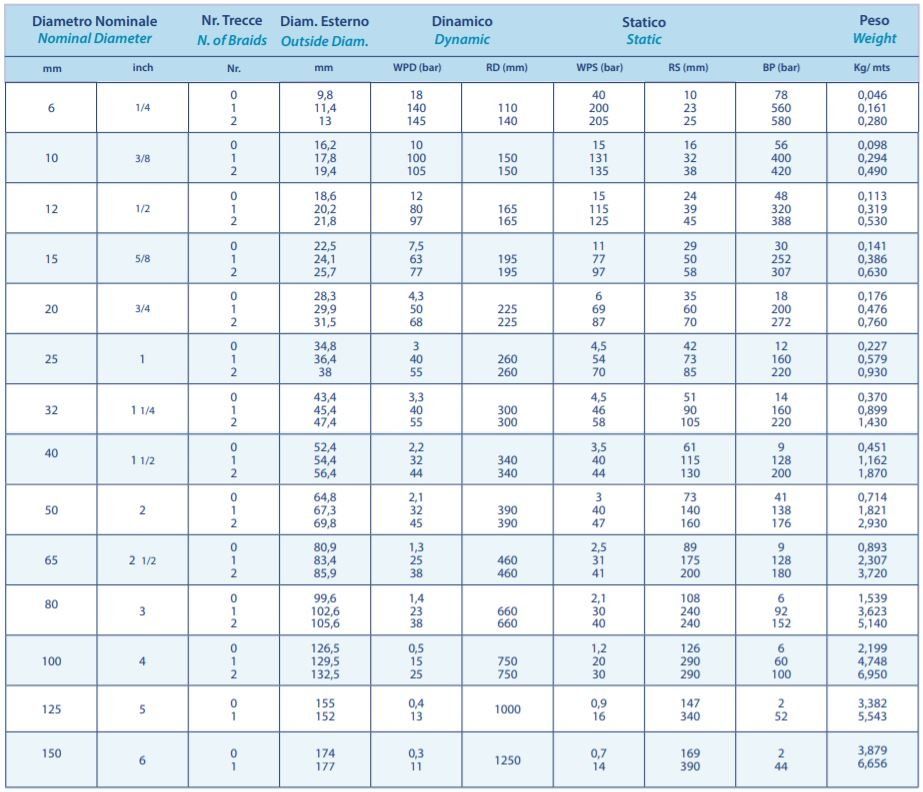

PARNOR

Flexible metal tube, formed by parallel waves obtained by hydraulic forming with longitudinal welding.

Material: AISI 316L / EN X2 Cr Ni Mo 1712-2 / DIN 1.4404 tube AISI 321 / EN X6 Cr Ni Ti 1810 / DIN 1.4541 braid AISI 304 / EN X5 Cr Ni 1810 / DIN 1.4301 braid PN0 = PARNOR without braid PN1 = PARNOR with 1 braid PN2 = PARNOR with 2 braids WPD (bar): Max dynamic operating pressure at 20 ° C RD (mm): Dynamic bending radius WPS (bar): Max static operating pressure at 20 ° C RS (mm) : Static radius of curvature BP (bar): Burst pressure

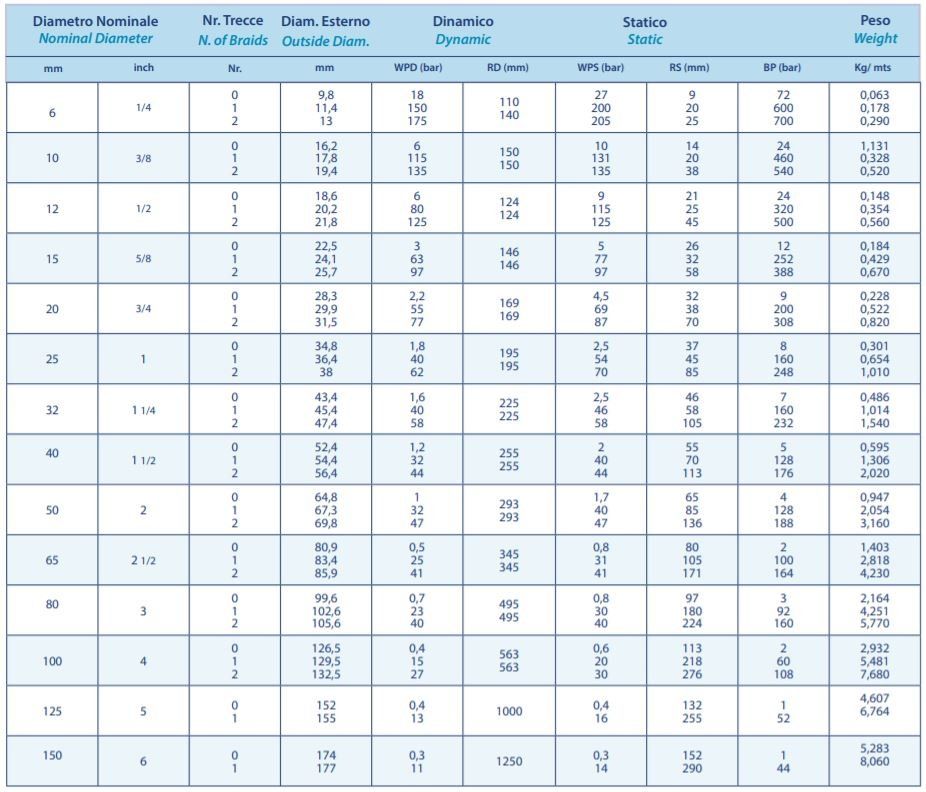

PARRAP

Extraflexible metal tube, formed by parallel omega shaped waves with narrow pitch obtained by hydraulic forming with longitudinal welding.

Material Pipe AISI 316L / EN X2 Cr Ni Mo 1712-2 / DIN 1.4404 Pipe AISI 321 / EN X6 Cr Ni Ti 1810 / DIN 1.4541 Braid AISI 304 / EN X5 Cr Ni 1810 / DIN 1.4301 PN0 = PARRAP without braid PN1 = PARRAP with 1 braid PN2 = PARRAP with 2 braids WPD (bar): Max dynamic operating pressure at 20 ° C RD (mm): Dynamic bending radius WPS (bar): Max static operating pressure at 20 ° C RS (mm): Static bending radius BP (bar): Burst pressure

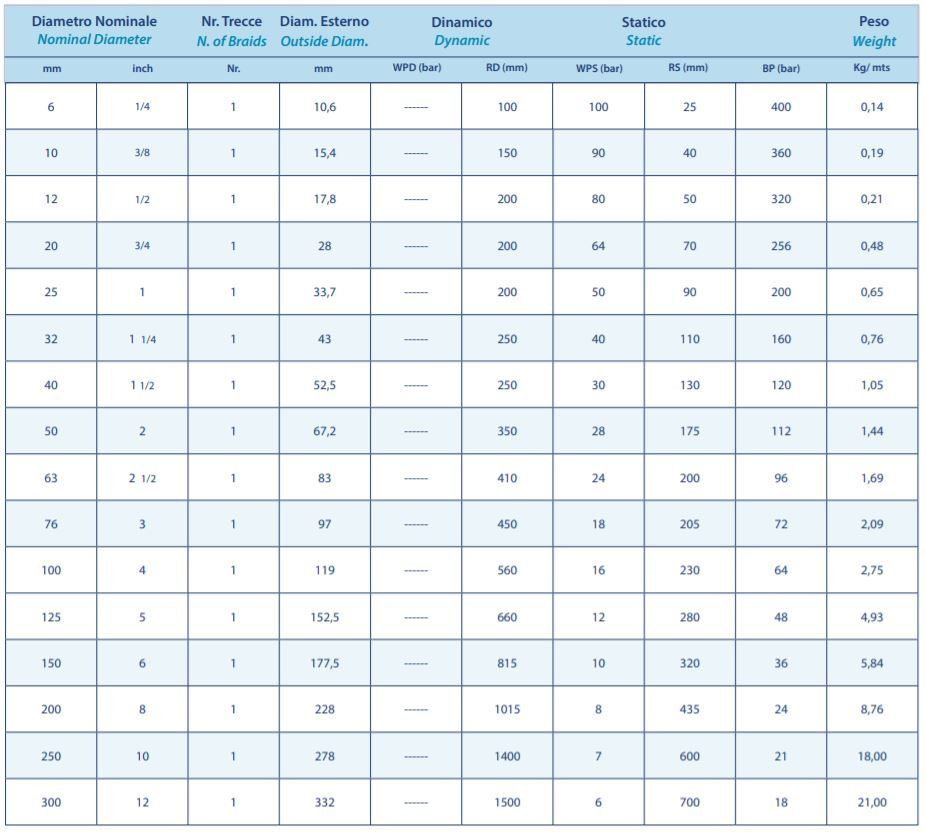

MEC-1

Flexible metal tube formed by parallel waves with narrow pitch mechanically obtained by longitudinal welding